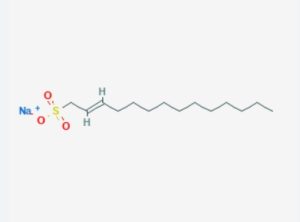

Comparative Analysis of Sodium Dodecyl Sulfate (SDS) and Lithium Dodecyl Sulfate (LDS)

From a Manufacturer’s Perspective

Sodium Dodecyl Sulfate (SDS)

Production Costs

- Raw Material Costs: The primary raw materials for SDS are dodecyl alcohol and sulfuric acid. These materials are readily available in the market and their prices are relatively stable.

- Production Process: The production process for SDS is well-established and involves steps like esterification, sulfonation, and neutralization. The technical barrier is relatively low, making it suitable for large-scale production.

Product Quality Control

- Purity: Strict control of reaction conditions during production is essential to ensure product purity. High-purity SDS is more competitive in the market.

- Stability: SDS needs to be stored and transported in a dry environment to prevent moisture absorption that could degrade its quality.

Market Demand

- Wide Applications: SDS is widely used in detergents, personal care products, textile dyeing, and other industries. The market demand is high, and sales channels are diverse.

- Intense Competition: Due to the relatively simple production process, there are numerous manufacturers in the market, leading to intense competition.

Lithium Dodecyl Sulfate (LDS)

Production Costs

- Raw Material Costs: The main raw materials for LDS include dodecyl alcohol and lithium sulfate. Lithium sulfate is more expensive and its price is significantly influenced by fluctuations in lithium resource prices.

- Production Process: The production of LDS is relatively complex, involving the synthesis and purification of lithium salts. The technical barrier is higher, making it unsuitable for small-scale production.

Product Quality Control

- Purity and Consistency: The purity and consistency of LDS significantly impact the performance of the final product. Precision control of reaction conditions and purification processes is crucial during production.

- Stability: LDS should be stored and transported in a moisture-free and dark environment to maintain its chemical stability.

Market Demand

- Application Areas: LDS is primarily used in high-end detergents, cosmetics, and personal care products, favored for its excellent surface activity and low irritation properties.

- Market Competition: Due to the higher production costs and technical barriers, there are fewer manufacturers in the market, leading to relatively moderate competition.

Usage Scenarios

Sodium Dodecyl Sulfate (SDS)

Household Cleaning Products

- Laundry Detergent: SDS, as an efficient surfactant, is widely used in laundry detergents, effectively removing stains from clothing.

- Dishwashing Liquid: Adding SDS to dishwashing liquid enhances its grease-removing capabilities and creates rich foam.

Personal Care Products

- Shampoo: SDS cleanses the scalp and hair in shampoo, while also producing abundant foam.

- Body Wash: As a key ingredient in body wash, SDS effectively cleanses the skin and provides a good foaming experience.

Industrial Applications

- Textile Dyeing: In the textile dyeing industry, SDS acts as a penetrant and dispersant, enhancing the uniformity and adhesion of dyes.

- Metal Cleaning: SDS can be used for cleaning metal surfaces, removing grease and grime.

Lithium Dodecyl Sulfate (LDS)

High-End Detergents

- Concentrated Laundry Detergent: LDS, with its high efficiency and low toxicity, is commonly used in high-end concentrated laundry detergents, suitable for both machine and hand washing.

- Premium Dishwashing Liquid: In premium dishwashing liquids, LDS provides excellent cleaning power and a mild user experience.

Cosmetics and Personal Care Products

- Gentle Facial Cleanser: LDS’s low irritation properties make it an ideal ingredient for gentle facial cleansers, suitable for sensitive skin.

- Baby Care Products: Due to its high safety profile, LDS is widely used in baby shampoos, body washes, and other care products.

Special Applications

- Medical Cleaning Products: LDS excels in medical cleaning products, effectively removing stains and bacteria from medical instruments.

- Food Contact Material Cleaning: With its low toxicity, LDS can be used to clean food contact materials, ensuring food safety.

Conclusion

In summary, sodium dodecyl sulfate (SDS) and lithium dodecyl sulfate (LDS) each have their advantages and disadvantages in terms of production and usage scenarios. SDS holds a significant position in the market due to its mature production process and wide range of applications, but faces intense competition. LDS, while having higher production costs and technical barriers, offers promising prospects in high-end detergents and cosmetics, with relatively moderate competition. Users should make informed choices based on their specific needs and application scenarios.

ORID is a leading surfactant production and R&D company dedicated to delivering high-performance, reliable SDS and LDS solutions to the market. We are committed to providing exceptional quality and technical support, ensuring your products meet the highest standards. Contact us today to discuss your specific needs and explore how our surfactant solutions can enhance your product formulations.