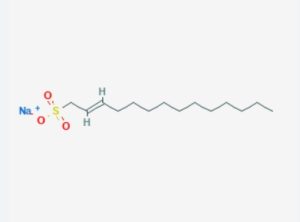

Sodium vinylsulfonate is a highly reactive, water-soluble monomer that is used to modify adhesives and enhance their properties. Its inclusion in adhesive formulations significantly broadens their application spectrum, especially where performance in wet conditions or adhesion to difficult substrates is required. Here’s how sodium vinylsulfonate is applied in adhesives:

1. Improving Adhesion: Sodium vinylsulfonate can improve the adhesion of a variety of adhesives to difficult-to-bond surfaces, including metals, plastics, and glass. This is particularly useful in industries such as automotive and electronics, where durable and reliable adhesion is critical.

2. Enhancing Water Resistance: By incorporating sodium vinylsulfonate into adhesive formulations, manufacturers can increase the water resistance of the final product. This makes the adhesive more suitable for use in moist or underwater applications, such as in marine, construction, and repair adhesives.

3. Increasing Flexibility: Adhesives modified with sodium vinylsulfonate exhibit increased flexibility, making them more effective for bonding materials that may expand, contract, or flex during use. This property is advantageous in applications such as flexible packaging and sealants.

4. Polymers and Copolymers Formation: Sodium vinylsulfonate can polymerize with itself or copolymerize with other monomers to form polymers or copolymers that serve as the base for high-performance adhesives. These polymers can offer desired properties such as high tack, flexibility, and strength.

5. Enhanced Durability: The chemical structure of sodium vinylsulfonate contributes to the formation of adhesives that are more resistant to chemical degradation, UV light, and temperature variations. This leads to longer-lasting adhesives that maintain their performance over time.

6. Compatibility with Other Components: Sodium vinylsulfonate can be easily mixed with other monomers and additives, allowing adhesive manufacturers to tailor formulations to meet specific requirements for various applications.

Sodium vinylsulfonate’s ability to enhance the performance characteristics of adhesives makes it a valuable component in the formulation of industrial adhesives used across a wide range of sectors. Its applications span from everyday consumer products to specialized industrial uses, where superior adhesive properties are essential.