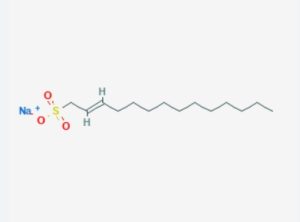

Sodium Lauryl Sulfate (SLS), at a typical industrial purity level of around 92%, is a highly effective surfactant used in various industrial cleaning products. The specific ’92’ designation suggests a particular purity grade commonly found in industrial settings. Here’s how SLS92 is utilized in industrial detergents:

1. Powerful Cleansing Agent: SLS92, with its strong surfactant properties, serves as a potent cleansing agent. It’s effective at breaking down and removing oily and greasy residues, which are commonplace in industrial settings, from machinery and work surfaces.

2. High Foaming Capability: SLS92 is known for producing a high level of foam, which is beneficial in certain industrial cleaning processes as it can lift dirt particles and keep them suspended in the foam, preventing them from resettling on cleaned surfaces.

3. Emulsification: It helps in emulsifying fats, oils, and greases, which means it breaks these substances into smaller droplets that can be rinsed away with water, allowing for efficient cleaning of parts and surfaces in industrial operations.

4. Use in Degreasers: Due to its strong de-greasing properties, SLS92 is often used in products designed to clean engine parts, garage floors, and automotive exteriors where grease and oil spillage is common.

5. Wetting Agent: It also acts as an excellent wetting agent, allowing the cleaning solution to spread more easily over surfaces, thereby increasing the contact area and improving the overall cleaning process.

6. Compatibility with Hard Water: SLS92 can maintain its cleaning efficiency even in the presence of hard water ions, which are typically problematic for many surfactants. Thus, it’s effective in a variety of water conditions that industrial settings may present.

7. Stability and Storage: This compound is stable over a range of temperatures and pH levels, making it suitable for the demanding environments found in industrial applications. Its stability also eases storage requirements.

8. Cost-Effectiveness: SLS92 is a cost-effective option for industries that require large volumes of detergents, as it provides a good balance between performance and expense.

Despite its effectiveness as a cleaning agent, the use of SLS92 may be closely monitored in industrial settings due to its potential to be harsh on skin upon prolonged contact and its environmental impact. Protective measures are usually advised for workers handling concentrated forms of this chemical. Additionally, industries may seek SLS92 varieties that are formulated to be more environmentally friendly, with improved biodegradability, to meet regulatory standards and sustainability goals.